Hanspeter is currently building a Tumbleweed in Germany, a country where the tiny house movement is in its inception, but this isn’t his first experience as a woodworking pioneer. In June of 2000, he traveled to Mongolia to construct the first wood frame house in Ulaanbaatar for a local family. “This,” he says, “was one of the best experiences of my life.”

Hanspeter began construction of his tiny home last summer, but since he is building one of the first tiny homes in Germany he has encountered a few unique challenges. “In Germany, we are not allowed to bolt the structure permanently to the trailer,” Hanspeter explains, “So I invented a system to plug my tiny house into the trailer railings.” In doing so, his tiny home is now categorized as a “load.”

Hanspeter faced his next challenge when he weighed his half-finished tiny home and was forced to cut back on using heavy materials. Tumbleweed trailers are rated for either 10,000 or 15,000 lbs, but as Hanspeter explains: “The sturdiest trailers available in Europe that I know of are 3.5 tons (about 7,700 lbs). My trailer is a 2.7 tons trailer (about 6,000 lbs). The only solution for building tiny homes in Europe is to build lighter and smaller.”

Since discovering weight might be an issue, Hanspeter has put his home on a diet, employing only light weight materials. For example, he used aluminum instead of steel roofing and styrofoam insulation instead of wood fiber. Even with taking these precautions, Hanspeter’s most recent weighing neared 5,300 lbs. That leaves him only 700 lbs for the remainder of his interior build.

“I am aware that the Tiny House might still become too heavy once fully equipped. One option is to change the axles, the breaks and the towing bar.” Hanspeter contemplates, “I’m also currently investigating if the trailer manufacturer is able to build a 3.5 ton trailer with the same dimensions and the same railing as my current trailer.” If that option proves available, Hanspeter’s Tiny House could be transposed onto the new heavy-duty trailer (as mentioned earlier, his home was engineered to be “plugged” into the trailer, rather than permanently fixed). Although costly, he believes upgrading the trailer would be the ideal solution.

2) Build with the lightest materials you can find and keep the thickness of floor, roof and walls in reasonable limits. Weight will add up fast and every pound counts in the end.

3) Try to get in touch with other builders of Tiny Houses, Circus Wagons, Vardos and Shepherds Huts. In Europe, this is the most difficult task.

————————————-

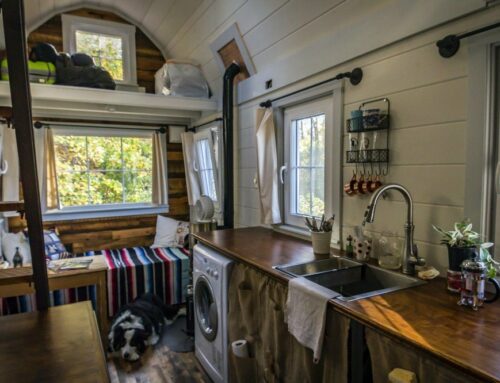

*All photos provided by Hanspeter & Black Forest Tiny House

*More information on Hanspeter’s build can be found on his website here.

Leave A Comment